I’m back home, more tired than when I left. A small pile of orders is waiting to be picked, packed, and posted. They’ll go out tomorrow.

I’m always trying to make the eShapeOko kit better. I made three changes:

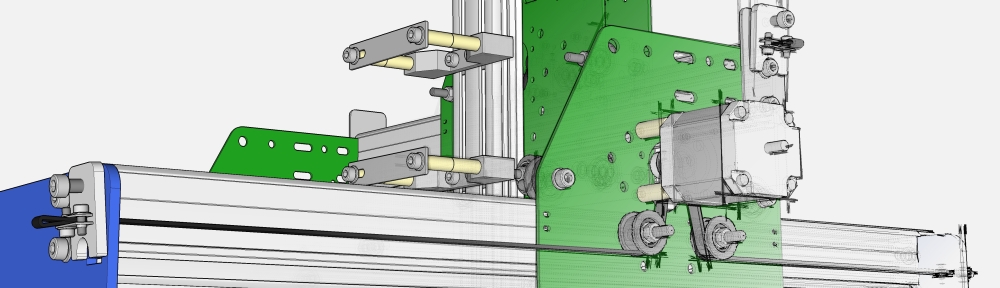

- Thicker nylon spacers. They have 50% larger cross-section, so they should help make the X carriage more rigid.

- New belt clamps. The kits now come with laser-cut belt clamps which take M5 screws and nuts to tighten. They are a neater solution than the zip ties.

- Redesigned belt tensioners. The new ones are longer, and instead of a half-circle cut-out for the head of the top X rail screw, they now have a large round hole.

All kits from the third batch got the new belt clamps instead of the zip ties (a pleasant surprise, I hope), and some got the new belt tensioners. The fourth batch will get the thicker nylon spacers, too.

Speaking of spacers, I have a sample of aluminium spacers on their way to me. If they’re good, they’ll go in the store as an upgrade. Aluminium spacers help make the X carriage even more rigid, and they allow the bolts to be tightened much more without fear of squeezing the spacers. I’ll offer them in kits for dual-X (twelve 25.4mm spacers plus two 6.35mm spacers) and individually. I haven’t ordered any 19.05mm spacers in aluminium, because they’re used only for the single-X (no point in making the single-X carriage more rigid) and for the spindle mount (where nylon is perfectly fine).

Also on their way are Pololu drivers (green, black and the new purple ones), emergency stop push buttons, and a few other little things.

The emergency stop button sounds good to me, having had one or two mishaps with my 3D printer in the past. Is it a mains switch, or low voltage into electronics kind of switch?

I’ve currently got a low voltage switch, which to be honest doesn’t always work…

It’s rated for mains voltage operation, but that would require a proper enclosure to be safe. My advice is to leave mains voltage alone and have it interrupt the connection between the positive output of the DC power supply and the rest of the system. The switch is rated 10 A, so that shouldn’t be a problem even for a 3D printer with a heated bed, if using 24 V (5-6 A for the bed, 1 A for the extruder, and no more than 3 A for the steppers).

If using a spindle with a relay, cutting power to the relay should also stop the spindle, unless the relay itself is defective. That is a risk I, personally, would be willing to take, to avoid having to use the e-stop switch with mains voltage.