Difference between revisions of "GAUPS 1.0 Instructions"

| Line 163: | Line 163: | ||

Do not make or break any connections while the board or the Arduino are powered. There is a high risk of destroying the drivers and/or the Arduino. | Do not make or break any connections while the board or the Arduino are powered. There is a high risk of destroying the drivers and/or the Arduino. | ||

| − | [[File:Wiring.jpg|600px]] | + | [[File:GAUPS 1.0 Example Wiring.jpg|600px]] |

This image shows an example configuration: | This image shows an example configuration: | ||

Revision as of 20:45, 2 October 2013

Assembly

It's easiest to assemble the board in the order of component height, leaving the tallest last. For the parts with long leads, trim them as soon as you've soldered them. The instructions assume the board is held with the driver labels ("X AXIS" etc) the right way up, as shown.

| Step | Image | Instructions |

|---|---|---|

| 1 |

|

Solder R1 (10 kΩ resistor). |

| 2 |

|

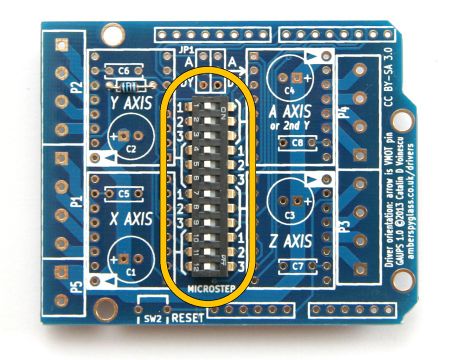

Solder SW1 (12-way DIP switch). Orient it numbers to the left, "ON" text in the upper-right corner. The 1, 2 and 3 labels will match the 1, 2 and 3 silkscreen labels for the A axis. |

| 3 |

|

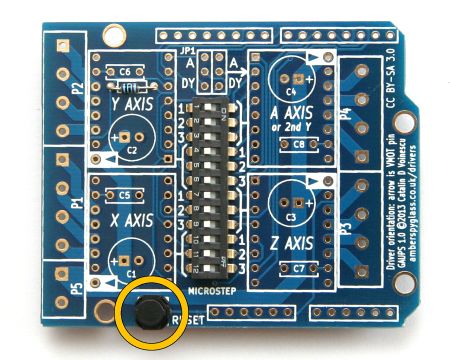

Solder SW2 (push-button), taking care not to overheat it. |

| 4 |

|

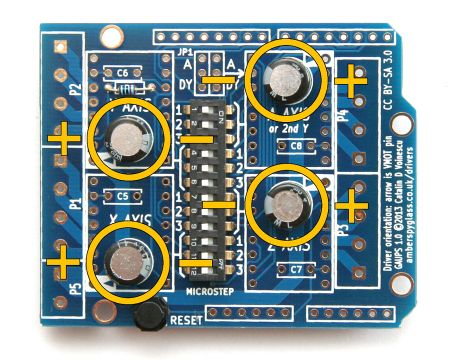

Solder C1, C2, C3, C4 (47 µF 35 V capacitors), paying attention to the orientation. Install with the negative terminal (shorter lead, marked with a stripe on the body of the capacitor) toward the middle of the board. |

| 5 |

|

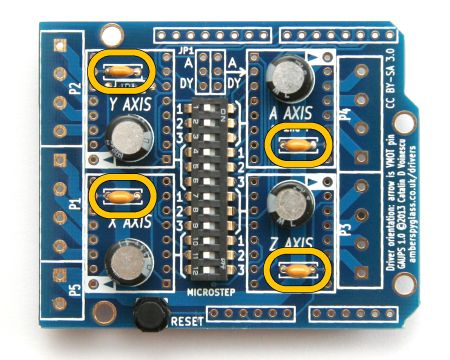

Solder C5, C6, C7, C8 (100 nF capacitors). |

| 6 |

|

Solder the eight 8-way female headers for the drivers. |

| 7 |

|

Solder JP1 (2×3-pin male header). The holes for it are very tight (sorry!). The best way is to push it in with a flat, rigid object. |

| 8 |

|

Solder the two 6-way and two 8-way Arduino stacking headers, taking care to not to deposit solder on the long pins (except where they meet the PCB, of course). Make sure the pins are straight and parallel before soldering them. |

| 9 |

|

Join one 2-way and two 4-way screw terminals, by sliding the little dovetails into the slots. Solder them as P5, P1 and P2, with the openings for the wires toward the outside of the board. Join the remaining two 4-way screw terminals. Solder them as P3 and P4. |

| 10 |

|

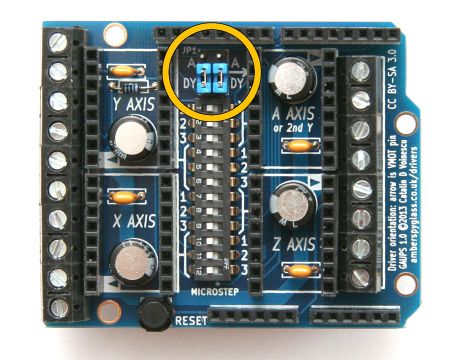

Install two jumpers on JP1, either in the DY position (shown) or the A position (not shown). See jumper settings below. Check all the soldering, remove any loose bits of solder, insert into the Arduino Uno, and you're done! |

Driver Orientation

Driver pin VMOT (motor supply voltage) is marked with an arrow on the silkscreen (please note that this is different from the beta version). The motor outputs (1A, 1B, 2A, 2B) face the respective screw terminals. The electrolytic capacitor is near the VMOT pin, and the yellow ceramic capacitor is near the VDD pin. The digital inputs are toward the middle of the board.

Note that two drivers (X and Y) are oriented one way, the other two (Z and A) the other way.

Jumper Settings

For Dual-Y operation, the A driver takes the same control signals (STEP and DIR) as the Y driver, acting as a second Y driver instead of a fourth independent axis. Install two jumpers in the positions marked 'DY' on the board.

For 4-axis operation (or spindle relay in the A axis slot, instead of a driver), STEP and DIR for the A driver come from Arduino pins D12 and D13. Install two jumpers in the positions marked 'A' on the board.

| JP1 | ||||

|---|---|---|---|---|

| Dual-Y | 4 axes | |||

| • | • | • • |

• • | |

| • • |

• • | |||

| • | • | |||

Switch Settings

DIP switches are OFF to the left (the side of the switch with the numbers), ON to the right (the side labelled "ON").

Microstepping is controlled independently for each of the four drivers. Each driver has three switches associated with it. The silkscreen shows which switches apply to which driver.

| SW1 switch | Driver Input |

A4988 and DRV8825 | A4988 | DRV8825 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| X axis | Y axis | Z axis | A axis | 1 × | 2 × | 4 × | 8 × | 16 × | 16 × | 32 × | |

| 10 | 4 | 7 | 1 | MS1 | OFF | ON | OFF | ON | ON | OFF | ON |

| 11 | 5 | 8 | 2 | MS2 | OFF | OFF | ON | ON | ON | OFF | ON |

| 12 | 6 | 9 | 3 | MS3 | OFF | OFF | OFF | OFF | ON | ON | ON |

For instance, to set a DRV8825 driver on the Z axis to 8 × microstepping, set switches 7 on, 8 on, 9 off. In the Dual Y configuration, it's simplest to use the same type of driver and motor for both the Y axes (Y and A), and use the same microstepping configuration for both (switches 1–3 same as switches 4–6).

Connections

The motor screw terminals are connected to the driver outputs nearest to them, in the same order.

The motor power supply input is P5, the two bottom screw terminals in the block of ten on the left side of the board. Positive is next to the X axis motor terminals, negative at the bottom edge of the board. Please note that this is different from the beta version. The polarity is marked on the silkscreen on the back of the board (there was no room on the front).

Do not make or break any connections while the board or the Arduino are powered. There is a high risk of destroying the drivers and/or the Arduino.

This image shows an example configuration:

- Four drivers and four motors

- Dual-Y (two Y motors, each with its own driver)

- 16 × microstepping on the X and Y axes

- Half-stepping (2 ×) on the Z axis

- Pololu A4988 green drivers (note that other driver modules may have the trimpot in a different location, so do not use it to decide the driver module orientation. Always check the pin labels).

Also, when using GRBL 0.8 or 0.9 with the "invert mask" set to 0, and the motors we carry in our store, moving each axis in the positive direction causes the motors to turn as follows (as viewed when looking into the shaft):

| Axis | Motor | Axis Positive Direction | Motor Spin Direction |

|---|---|---|---|

| X | Right | Counter-clockwise | |

| Y | Left (Y driver) | toward the rear |

Counter-clockwise |

| Right (A driver) | Clockwise | ||

| Z | Up | Clockwise | |

This is the standard direction of travel for a dual-motor dual-Y drive eShapeOko with any of the supported eShapeOko belt configurations (teeth down, belt going under the idler wheels and over the belt pulley). Reverse the direction of X and Y motors (by reversing the connections, black–green–blue–red instead of red–blue–green–black) for the original Shapeoko belt configuration (belt teeth up, going over the idler wheels and under the belt pulley).

Note that not all motors from all manufacturers turn in the same direction when wired the same, although this seems to be the most common case. If your motor has different color wires, always determine the correct pairing before wiring the motors, to avoid damage to the drivers. Any configuration will work, as long as the wires in each pair are next to each other (pins 1 and 2 one pair, pins 3 and 4 another pair).